Engineering & Design Services

Planning, Design, & Modeling

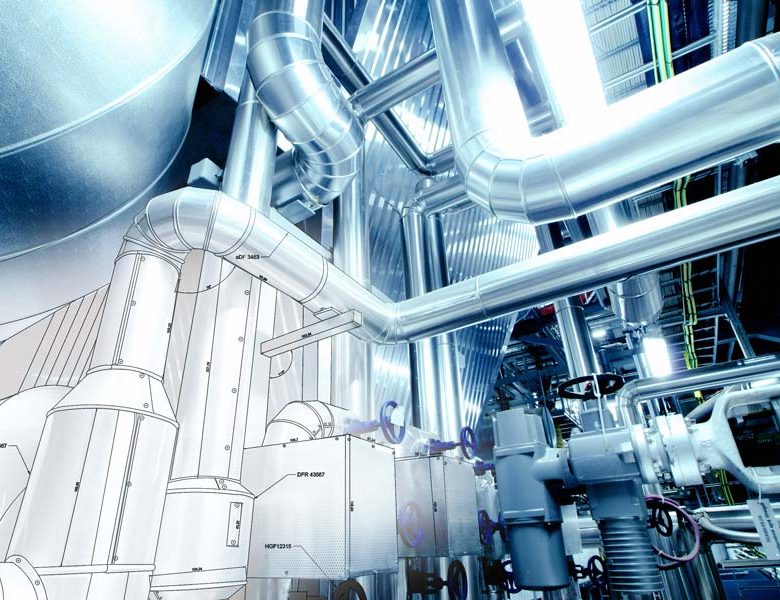

Planning to expand existing facilities, add a new modular process unit, or install skid-mounted packaged equipment comes with unique design challenges... Meeting these challenges while providing ergonomic access for operations and equipment maintenance through the entire operating life of a project is where our designers earn their pay.

get in touch

Whatever the industry, the drive for efficient use of available space and resources remains the same. Increasing capacity within the confines of an existing plot plan or modularizing a production unit to minimize onsite construction labor and reduce plant outage windows takes careful planning.

Principal Technology’s designers have decades of experience with modular fabrication and packaged equipment. While getting the design right is half of the construction battle, every project we undertake begins with the plant Operators in mind.

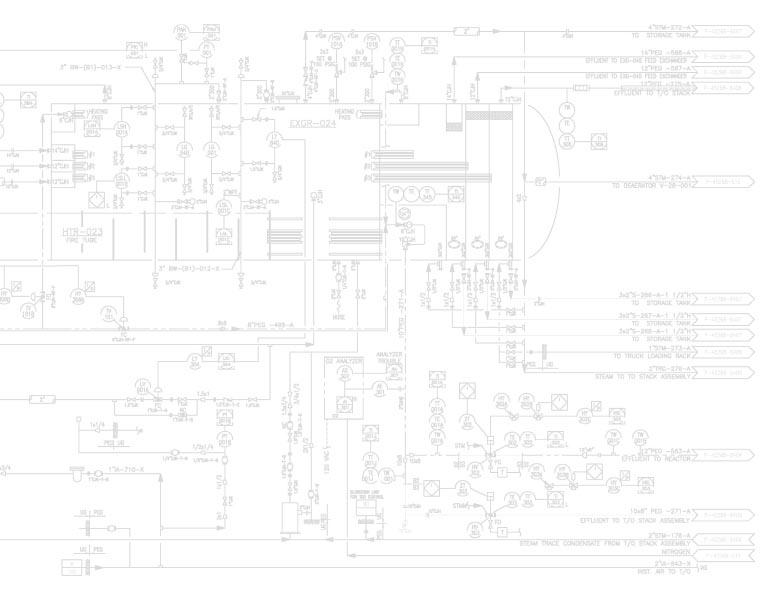

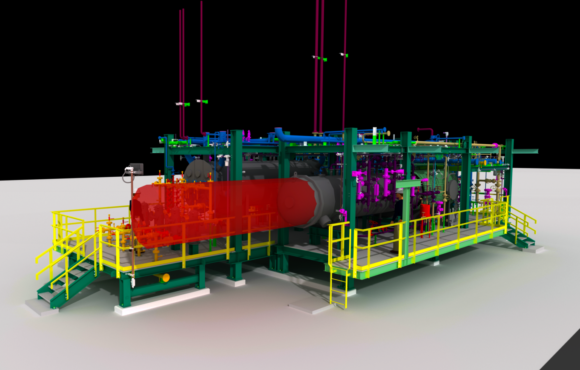

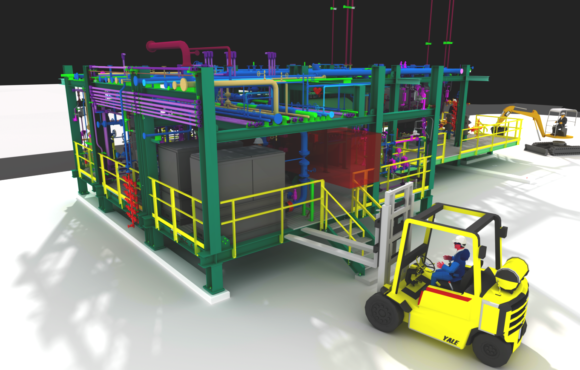

Our designers create detailed 3D Models that evolve throughout the life of a project—starting with space planning and the conceptual layout of major equipment through an interactive review with all of the project stakeholders.

Finally, we provide all Stakeholders access to a comprehensive Approved for Construction 3D Model that incorporates all equipment, piping, I&E, and structural components, including virtualized maintenance access and operations areas.

We actively engage the fabrication trades and construction teams to review the 3D Model to aid the build phase of our projects. We also use this valuable tool with the client’s operations team to use as a valuable training tool to prepare for their new equipment.

related expertise

Engineering Consulting Services

Being a trusted advisor to our clients is a cornerstone of our mission to provide valued engineering solutions. We cannot solve every problem, but our commitment to our clients is to understand their unique challenges and deliver independent technical advice and support.

learn more

Process & Mechanical Engineering Services

The Process and Mechanical Engineers at Principal Technology have decades of experience in process design, equipment design, and troubleshooting for industrial, manufacturing, petroleum, and energy clients. We can help design your process and equipment, rate existing units, troubleshoot and optimize current operations, and train your operators. Whether it is bringing to life an idea from the back of a napkin or expanding existing units, our engineers can find the right solution for your process.

learn more

Instrument & Control Systems Engineering

Advanced instrumentation and control system design is a critical element of our mission to provide efficient engineering solutions.

learn more

Electrical Engineering Services

The electrical engineers at Principal Technology have years of experience working on heavy commercial, industrial, and manufacturing projects. Our electrical engineers can provide engineering expertise to support your project design, permitting, construction, and operations, from new installations and facility expansions to performance, power, and safety studies.

learn more

Prototyping Services

As an engineer or designer who likes to see your work come to life, Prototype and Proof-of-Concept projects are just plain fun!

PTI's multiple discipline-technical expertise and professional experience have afforded us the pleasure of working on numerous prototype and proof-of-concept development projects.

learn more

Operations Support Services

From process performance evaluation to modernizing legacy equipment, our process, controls, and electrical engineers help clients improve process system performance, extend the working life of your equipment assets, and maintain compliance with current safety standards.

learn more

Training Services

Teach, Show, Do, Review, and Apply... (We didn't invent it, but we use it).

Meaningful training is the cornerstone of our successful projects. Whether it is a basic control system that is new to your operations, a critical process safety or combustion management system, or a large operating plant... Principal Technology engineers are committed to the successful operation of any system we provide our customers - for the life of the equipment!

learn more

Sulfur Recovery

Principal Technology has 25 years of experience designing and building systems to remove and recover sulfur from process streams. Our Sulfur portfolio includes all units in the Sulfur Block - Amine Treating and Regeneration, Sour Water Strippers, Sulfur Recovery, Tail Gas Treating, Thermal Oxidizers and Incinerators, Sulfur Degassing, and Oxygen Enrichment. Our experience ranges from front-end engineering, operations support and training through Turn-key EPC of plants ranging in nameplate capacity from 2 LTPD to multi-train 1000+ LTPD facilities.

learn more

our work

Multi-Discipline Design Elements

Principal Technology designers understand that even the best piping and mechanical layout is only half of the challenge we undertake when designing compact modular equipment and process units. Our team demands tight collaboration with our entire engineering team.

We start our model development with the process equipment and line sizing, but it is not complete until the entire team provides their Stamp of Approval… pipe stress analysis, instrument location, and meter runs, electrical conduit and cable tray systems, structural design, lifting plans, and even flagging what components must ship loose and how the modules it will set on the truck…

All technical disciplines have input into the design of a successful project.

read more

Virtualized Operations and Maintenance Access

The shortcomings of a poorly designed unit are often visible even before construction is complete.

Our designers begin each project by asking the “What happens when?” questions for every major component of a unit. How will the operators interact with the equipment? What happens if you need to retube a boiler or heat exchanger? How will we pull a pump motor when it requires an overhaul?

We can eliminate future operations and maintenance headaches by answering these questions during the Conceptual Planning phase and by including virtualized operator and maintenance access areas in all phases of 3D model development.

read more