Engineering & Design Services

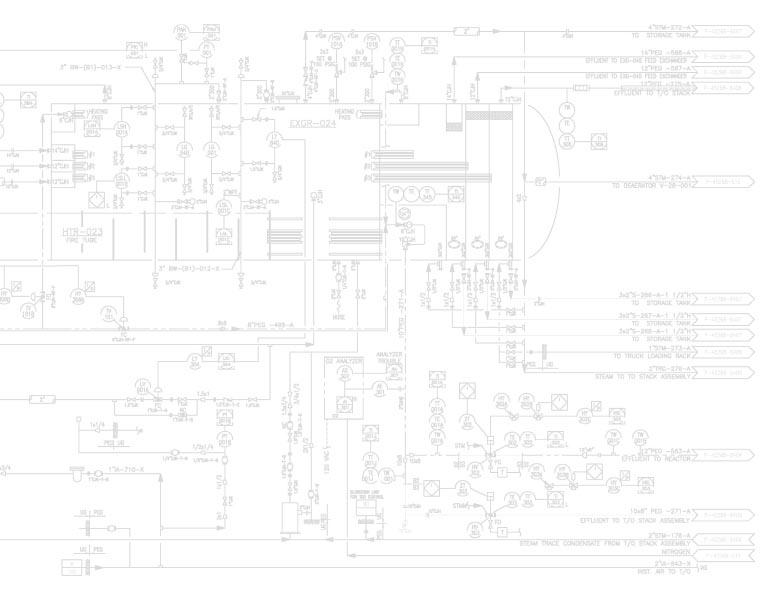

Electrical Engineering Services

The electrical engineers at Principal Technology have years of experience working on heavy commercial, industrial, and manufacturing projects. Our electrical engineers can provide engineering expertise to support your project design, permitting, construction, and operations, from new installations and facility expansions to performance, power, and safety studies.

get in touch

Our electrical engineers have extensive experience designing electrical systems for new facilities and plant expansions. We can start at the utility pole or from existing transformers and switchgear.

Our project portfolio includes everything from stand-alone rack-mounted starter racks, VFDs, and Heater Power Panels (HPP) to complete Motor Control Centers with advanced network connectivity and modular Power Distribution Buildings or E-Houses. PTI produces code-compliant designs for electrical gear and power systems to meet your current and planned expansion needs.

We also support our clients by conducting Power System Studies, Short Circuit and Relay Coordination Studies, Arc Flash Studies, and determining Flash Hazard Protection Boundaries.

related expertise

Engineering Consulting Services

Being a trusted advisor to our clients is a cornerstone of our mission to provide valued engineering solutions. We cannot solve every problem, but our commitment to our clients is to understand their unique challenges and deliver independent technical advice and support.

learn more

Process & Mechanical Engineering Services

The Process and Mechanical Engineers at Principal Technology have decades of experience in process design, equipment design, and troubleshooting for industrial, manufacturing, petroleum, and energy clients. We can help design your process and equipment, rate existing units, troubleshoot and optimize current operations, and train your operators. Whether it is bringing to life an idea from the back of a napkin or expanding existing units, our engineers can find the right solution for your process.

learn more

Planning, Design, & Modeling

Planning to expand existing facilities, add a new modular process unit, or install skid-mounted packaged equipment comes with unique design challenges... Meeting these challenges while providing ergonomic access for operations and equipment maintenance through the entire operating life of a project is where our designers earn their pay.

learn more

Instrument & Control Systems Engineering

Advanced instrumentation and control system design is a critical element of our mission to provide efficient engineering solutions.

learn more

Prototyping Services

As an engineer or designer who likes to see your work come to life, Prototype and Proof-of-Concept projects are just plain fun!

PTI's multiple discipline-technical expertise and professional experience have afforded us the pleasure of working on numerous prototype and proof-of-concept development projects.

learn more

Operations Support Services

From process performance evaluation to modernizing legacy equipment, our process, controls, and electrical engineers help clients improve process system performance, extend the working life of your equipment assets, and maintain compliance with current safety standards.

learn more

Training Services

Teach, Show, Do, Review, and Apply... (We didn't invent it, but we use it).

Meaningful training is the cornerstone of our successful projects. Whether it is a basic control system that is new to your operations, a critical process safety or combustion management system, or a large operating plant... Principal Technology engineers are committed to the successful operation of any system we provide our customers - for the life of the equipment!

learn more

Sulfur Recovery

Principal Technology has 25 years of experience designing and building systems to remove and recover sulfur from process streams. Our Sulfur portfolio includes all units in the Sulfur Block - Amine Treating and Regeneration, Sour Water Strippers, Sulfur Recovery, Tail Gas Treating, Thermal Oxidizers and Incinerators, Sulfur Degassing, and Oxygen Enrichment. Our experience ranges from front-end engineering, operations support and training through Turn-key EPC of plants ranging in nameplate capacity from 2 LTPD to multi-train 1000+ LTPD facilities.

learn more

our work

Arc Flash Study

PTI’s licensed electrical engineers provide arc flash studies for industrial and commercial facilities to help protect your employees and to meet the requirements of NFPA 70E. A comprehensive Arc Flash Analysis must be completed and reviewed at intervals not exceeding five years or after making significant changes to your electrical systems.

Principal Technology engineers conduct these studies and can assist your plant personnel in gathering the required technical data for your system, including:

- Auditing or producing a Power Distribution One-Line Drawing

- Gathering and documenting the size and ratings of your installed equipment

- Conducting Short Circuit and Coordination Studies to determine the incident energy and arc flash boundaries.

- Determine what Personal Protective Equipment (PPE) is required based on the study results.

- Producing Arc Flash Labels for each of your panels or enclosures.

read more

Modular Motor Control Center E-House

Plug and Play…. for industrial projects. Added congestion to an already busy plant, minimizing interruptions to ongoing facility operations, reducing outage cost by maximizing work performed off-site… These are just a few of the reasons clients opt for a modular construction approach to their projects.

PTI has 25 years working with clients to achieve these goals. One piece of this work is to modularize Motor Controls along with plant and safety control system. These systems are pre-wired and pre-tested before they pass through the gate at your plant.

read more

Power Distribution Center

Modular power distribution centers are an efficient way to provide a controlled environment manufactured quality without creating unnecessary congestion at an already busy construction site.

Principal Technology engineers and designers provide design-only or design-build services to produce these modular systems. Typical options include traditional HVAC, corrosive environment coatings, or purged and pressurized buildings suitable for Class 1, Div 2 hazardous areas.

read more

Water Disposal Facility Motor Control and Power Distribution Rack

Principal Technology electrical engineers and designers developed this 480 VAC, 600A power distribution rack which included multiple variable frequency motor drives, motor starters, low voltage transformers, breaker panels, process control panels, and UPS battery backup systems for a water disposal plant in West Texas.

Our system integration and fabrication group also constructed and prewired the system before shipping it to the plant for installation. PTI engineers routinely assist our clients with onsite construction, commissioning, and start-up support. Design only or design-build; our engineers and designers are ready to tackle your project.

read more