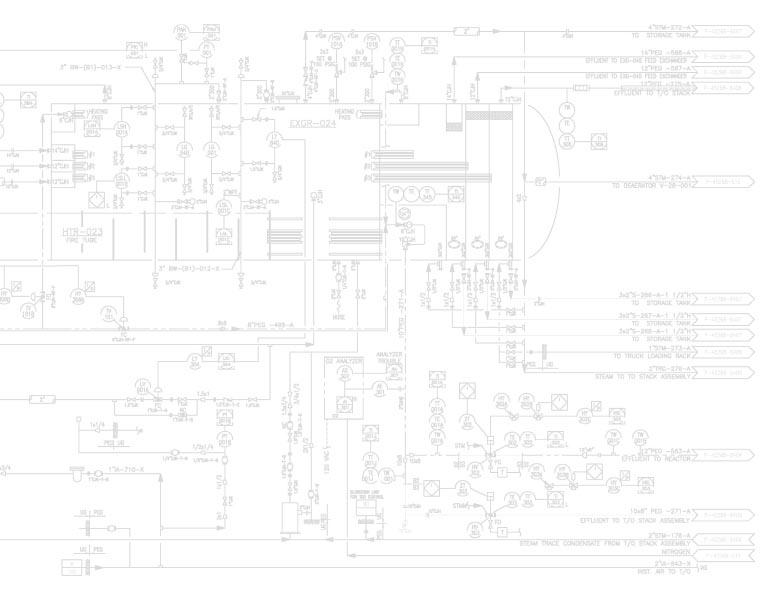

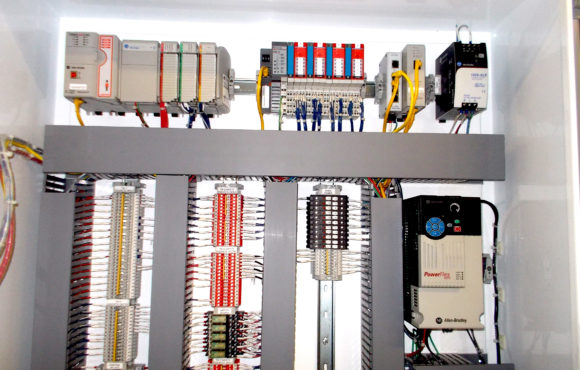

Automation & Control Systems

The tightly integrated engineering, system integration, and fabrication professionals at Principal Technology allow us to support diverse project scopes for a broad range of clients in various market sectors. Design-Build, Build-to-Print; cold-hardware, or turn-key logic development, configuration, testing, and anything in between, our project team is accustomed to tailoring our product and service offerings to meet our client's specific project needs.

learn more