Process Equipment Modules

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

learn moreSystem Fabrication Services

Modular E-Houses for Power Distribution, Analyzers, and Control Systems constructed from self-supporting Structural Insulated Panels (SIP) or with integral structural steel frames, available with packaged HVAC, pressurization, and purge ventilation systems.

get in touch

Our System Integration & Fabrication group constructs these custom building enclosures from powder-coated Structural Insulated Panels assembled on a structural steel base frame.

For small buildings, these panels provide an integral structural enclosure. Where required for larger buildings or unique project specifications, these panels tightly integrate with an independent structural steel frame or skeleton.

Our panels can be constructed in a range of thicknesses from 2″ to 8″ or can be sandwiched in multiple layers to meet the most demanding energy efficiency specifications.

Upgraded painting and coating systems, removable transoms and bulkhead panels, purged and pressurized HVAC for Hazardous Locations, and custom interior electrical systems are just a few of the optional design elements that our shop can incorporate into your building.

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

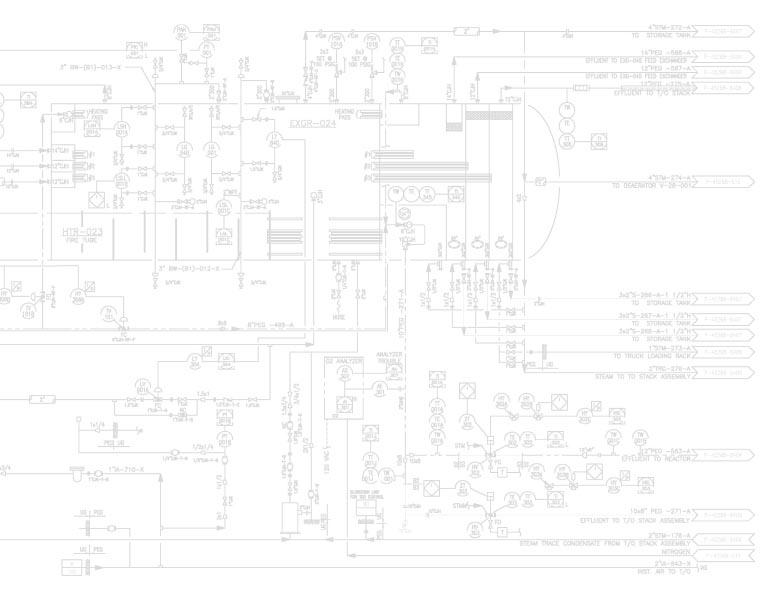

learn morePackaged Combustion Fuel Piping Systems provide tight integration of safety control, instrumentation, and critical burner fuel piping into a unitized system that is Factory Tested before shipping to your plant.

learn moreOur team can build the system to meet your filtration challenges for water, wastewater, sour water, amine, gas conditioning - Carbon filtration, cartridge, bag and sand media filters, ozonation, biological treating, and more.

learn morePrincipal Technology's welding department has extensive Stainless Steel piping and structural steel fabrication experience. Our welders are qualified to ASME XI and AWS D1.1 and 1.6.

learn moreNot all piping is equal... Specialty piping spools, including flow meter runs, welded jacketed piping systems, and alloy piping spools, can take a little extra care and attention. Principal Technology's fabrication group is experienced in meeting these challenges.

learn morePrincipal Technology has been designing, fabricating, and installing modular process units and equipment skid packages for over 25 years. Our senior managers and leadership team have dedicated most of their careers to the modular system design philosophy.

learn more

This pair of 8′ by 15′ purged and pressurized analyzer shelters are constructed from PTI’s pre-painted structural insulated panels. Principal Technology was also responsible for installing this project’s analyzers, sample systems, and calibration bottle racks.

Once shipped to our gulf coast client, our instrument engineers provided onsite commissioning and start-up support for the project.

Our skilled trade professionals fabricated this 15′ by 35′ power distribution and motor control building for a project in the Southwest United States. The project was designed for an elevated installation on piers provided by the client’s construction contractor.

Once fabrication was completed our System Integration team completed the installation of the client’s electrical switchgear and motor control equipment.

PTI Fabricated this large control building designed to house power distribution equipment installed after the building arrived at our customer’s facility in the western United States.

This building included an independent structural frame and drop-out rear access panels to provide room to install and service our client’s electrical gear.

Principal Technology is a full service engineering firm with additional support for system integration, fabrication, sulfur recovery, amine treating, and a wide selection of turnkey solutions.

Call 214-239-3900 or send us a message.