Our team was awarded this project to provide the surface systems engineering and design support, boiler control, produced water separation, and ongoing technical support for a heavy oil production project in the central United States.

The project was somewhat unique in that the steam assisted production technique developed by our client required separation of hot (flashing) produced fluid.

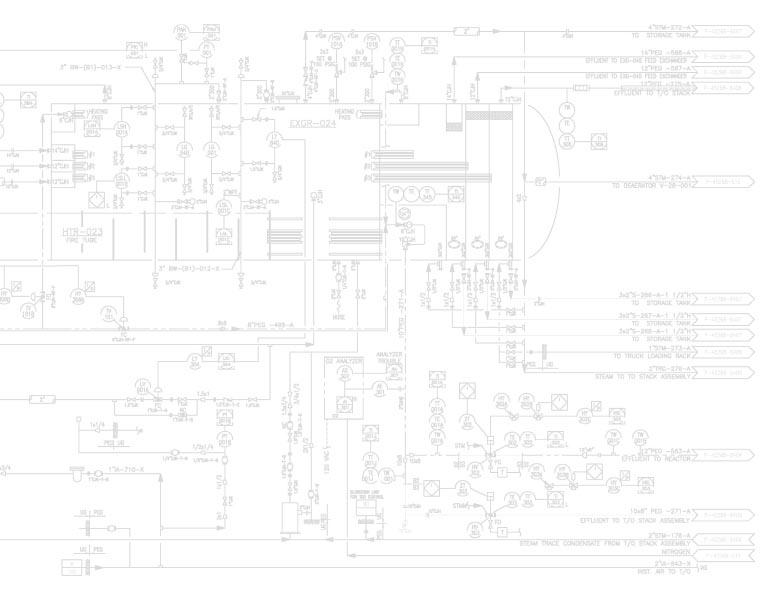

PTI’s responsibilities included the detailed design of the production pad, tanks and separators, boiler feedwater storage and treatment, electrical generator and power system design, as well as control system and data acquisition of data streams from the production equipment and downhole pressure and temperature instruments.

Our system integration and fabrication groups also supplied much of the project’s packaged equipment and control systems, including a modular control and operations building used by the operators who operated the site 24/7.