Engineering & Design Services

Instrument & Control Systems Engineering

Advanced instrumentation and control system design is a critical element of our mission to provide efficient engineering solutions.

get in touch

It is not too much to say that the managing partners of Principal Technology have a passion for instrumentation and control systems. The best reactor, pump, heater, burner, filter, or separator will not work without properly designed and integrated controls.

Our instrument engineers have decades of experience designing and specifying the right tool for the job in terms of field end devices ranging from standard flow, temperature, and pressure sensors to complex CEMS and Process Analyzer Systems.

Our control system engineers are well versed in most major Control and Automation platforms and can integrate your equipment or plant into an efficient ergonomic control system.

Our experience includes basic process control for continuous and batch plants, process safety systems including ISA S84 Safety Instrumented Systems, burner management systems, reactor control systems, SCADA remote monitoring, and satellite, radio, and cellular mobile platforms.

related expertise

Engineering Consulting Services

Being a trusted advisor to our clients is a cornerstone of our mission to provide valued engineering solutions. We cannot solve every problem, but our commitment to our clients is to understand their unique challenges and deliver independent technical advice and support.

learn more

Process & Mechanical Engineering Services

The Process and Mechanical Engineers at Principal Technology have decades of experience in process design, equipment design, and troubleshooting for industrial, manufacturing, petroleum, and energy clients. We can help design your process and equipment, rate existing units, troubleshoot and optimize current operations, and train your operators. Whether it is bringing to life an idea from the back of a napkin or expanding existing units, our engineers can find the right solution for your process.

learn more

Planning, Design, & Modeling

Planning to expand existing facilities, add a new modular process unit, or install skid-mounted packaged equipment comes with unique design challenges... Meeting these challenges while providing ergonomic access for operations and equipment maintenance through the entire operating life of a project is where our designers earn their pay.

learn more

Electrical Engineering Services

The electrical engineers at Principal Technology have years of experience working on heavy commercial, industrial, and manufacturing projects. Our electrical engineers can provide engineering expertise to support your project design, permitting, construction, and operations, from new installations and facility expansions to performance, power, and safety studies.

learn more

Prototyping Services

As an engineer or designer who likes to see your work come to life, Prototype and Proof-of-Concept projects are just plain fun!

PTI's multiple discipline-technical expertise and professional experience have afforded us the pleasure of working on numerous prototype and proof-of-concept development projects.

learn more

Operations Support Services

From process performance evaluation to modernizing legacy equipment, our process, controls, and electrical engineers help clients improve process system performance, extend the working life of your equipment assets, and maintain compliance with current safety standards.

learn more

Training Services

Teach, Show, Do, Review, and Apply... (We didn't invent it, but we use it).

Meaningful training is the cornerstone of our successful projects. Whether it is a basic control system that is new to your operations, a critical process safety or combustion management system, or a large operating plant... Principal Technology engineers are committed to the successful operation of any system we provide our customers - for the life of the equipment!

learn more

Sulfur Recovery

Principal Technology has 25 years of experience designing and building systems to remove and recover sulfur from process streams. Our Sulfur portfolio includes all units in the Sulfur Block - Amine Treating and Regeneration, Sour Water Strippers, Sulfur Recovery, Tail Gas Treating, Thermal Oxidizers and Incinerators, Sulfur Degassing, and Oxygen Enrichment. Our experience ranges from front-end engineering, operations support and training through Turn-key EPC of plants ranging in nameplate capacity from 2 LTPD to multi-train 1000+ LTPD facilities.

learn more

our work

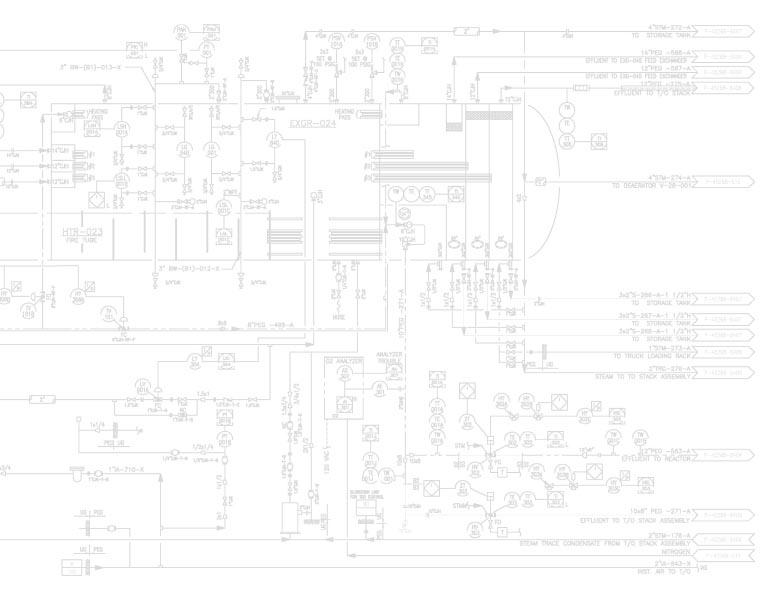

Continuous Emissions Monitoring Analyzer System

Principal Technology Instrument Engineers have experience providing turn-key design and integration services for a variety of process gas analyzer systems including Continuous Emissions Monitoring, process analyzers, flue gas, flare systems, sulfur recovery tail gas, and thermal oxidizers using analyzer technology from Horiba, Honeywell, Ametek, Rosemount Analytical, and Siemens.

Our typical system can include outdoor rack mount structures or fully enclosed modular analyzer shelters complete with HVAC, purge, and pressurization systems ready to drop in place at your plant.

read more

Modular Process Control and Safety Control System

PTI engineers and system integration group have the experience to tackle small stand-alone packaged control systems to large-scale plant-wide automation systems. This project included both the safety shutdown system and the process control system integrated into a single modular e-house that housed the unit’s motor control center. The system was designed and fabricated in Plano, Texas, and shipped to the end-user.

The pre-shipment Factory Acceptance Testing (FAT) included a fully hardwired function test and design review with our client’s engineering, operations, and maintenance stakeholders. The extensive design review and off-site function test reduced the installation and commissioning time by over 50% and minimized the on-site congestion during the project’s construction phase.

read more

Outsourced Engineering and Design Support

Principal Technology engineers routinely provide “outsourced” engineering services for clients who need to augment their in-house staff or to provide additional expertise to support their ongoing operations. We can provide onsite troubleshooting and performance consulting or specialty engineering services to produce design documents to support your project or operation including:

- Piping and Instrument Diagrams

- P&ID Audits and As-Builts

- ISA Instrument Datasheets

- Instrument and IO Lists

- Alarm Lists

- Conduit and Cable Schedules

- Cause and Effect

- Control Narratives

- Shutdown Narratives

- Boolean Logic Diagrams

- SAMA Control Logic Diagrams

- Installation Details and Bills of Materials (BOM)

- Control Valve Sizing

- Relief Valve Sizing

- Flow Meter Specifications

- General Instrument Selection and Specification

- Junction Box and Panel Wiring Schematics

- Control Panel Layout Drawings

- Loop Sheets

read more

Safety PLC Based Burner Management System

Modern Safety PLCs provide a unique combination of flexibility to interact with a plant’s DCS or Process Control System while maintaining the security and safety functions required for Burner Management and Flame Safeguarding traditionally provided by stand-alone control units.

National Fire Protection Association (NFPA) standards for Fluid Heaters (NFPA 87) and Ovens and Furnaces (NFPA 86) include requirements for Safety PLCs used in these systems.

PTI’s project portfolio includes numerous projects for applying these standards to new equipment construction as well as control system upgrades of legacy heaters and furnaces.

read more