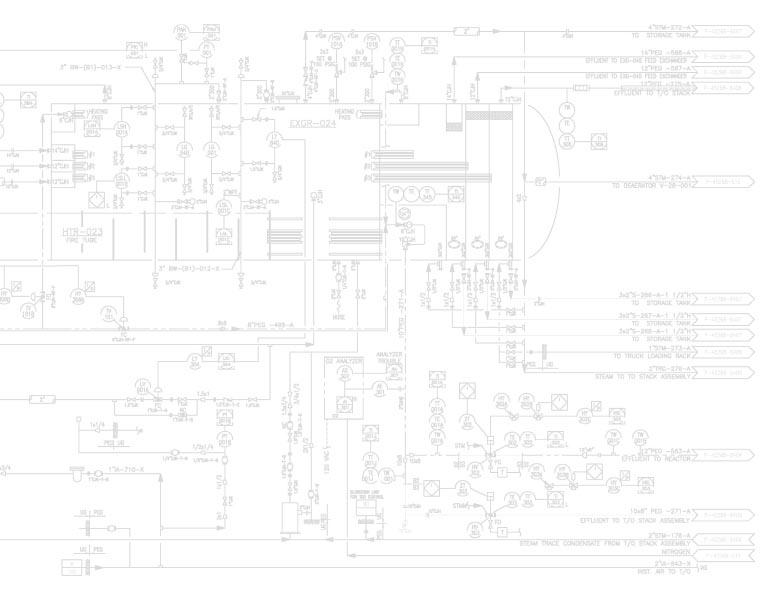

Process Equipment Modules

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

learn moreSystem Fabrication Services

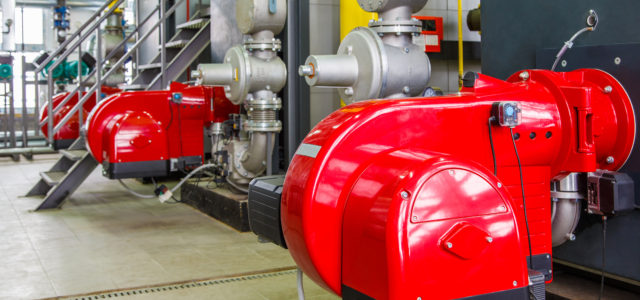

Packaged Combustion Fuel Piping Systems provide tight integration of safety control, instrumentation, and critical burner fuel piping into a unitized system that is Factory Tested before shipping to your plant.

get in touch

Combustion Control Equipment, Burner Management Systems, and Fuel System Piping Trains are excellent examples of system components that require tight integration to comply with industry codes such as NFPA and local and state regulations.

Principal Technology’s engineering, design, system integration, and fabrication professionals have an extensive portfolio of complete fuel system projects.

Whether your project requires a simple replacement fuel train or a complete system upgrade, our team can design, fabricate, and complete the system integration for your Combustion Management System.

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

learn moreOur team can build the system to meet your filtration challenges for water, wastewater, sour water, amine, gas conditioning - Carbon filtration, cartridge, bag and sand media filters, ozonation, biological treating, and more.

learn morePrincipal Technology's welding department has extensive Stainless Steel piping and structural steel fabrication experience. Our welders are qualified to ASME XI and AWS D1.1 and 1.6.

learn moreNot all piping is equal... Specialty piping spools, including flow meter runs, welded jacketed piping systems, and alloy piping spools, can take a little extra care and attention. Principal Technology's fabrication group is experienced in meeting these challenges.

learn morePrincipal Technology has been designing, fabricating, and installing modular process units and equipment skid packages for over 25 years. Our senior managers and leadership team have dedicated most of their careers to the modular system design philosophy.

learn moreModular E-Houses for Power Distribution, Analyzers, and Control Systems constructed from self-supporting Structural Insulated Panels (SIP) or with integral structural steel frames, available with packaged HVAC, pressurization, and purge ventilation systems.

learn more

Standard flame safeguard controllers or Safety PLC designed systems per NFPA-85, 86, or 87. Single and multi-burner capable with integral combustion blower controls for packaged burners.

Modular combustion fuel trains to NFPA standards for containment protection, pressure safeties, S/D valves, and valve proving; designed to accommodate annual system function testing.

ANSI/ISA S84 Safety Instrumented Systems and Safety PLCs. Our Engineering team works with each customer to design a system to meet your Safety Integrity Level (SIL) requirements.

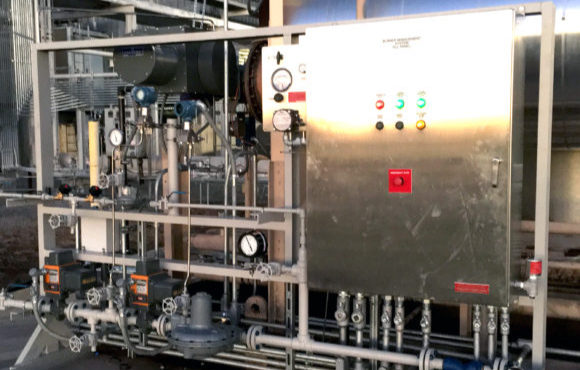

One of our clients in the Texas Panhandle needed to modernize this fluid process heater with a current burner management system, combustion fuel train, and replacement natural gas burner without scrapping the process heater which was still in great shape.

All of our business units were involved in this project from engineering and design, system integration, fabrication, and construction and start-up support. We selected a Safety PLC to perform the flame safeguard and combustion control functions which allowed the plant’s DCS to communicate directly with the heater control system.

PTI completed this project for a client in South Texas to replace their fuel train and combustion management system for a sizeable cabin-style process heater. The new system included a complete replacement for their fuel piping system, a new BMS, and replacement pilots and flame scanners.

Our team worked with the plant’s engineers to determine we could reuse the existing heater burners with minimal modifications, which helped the project’s capital budget.

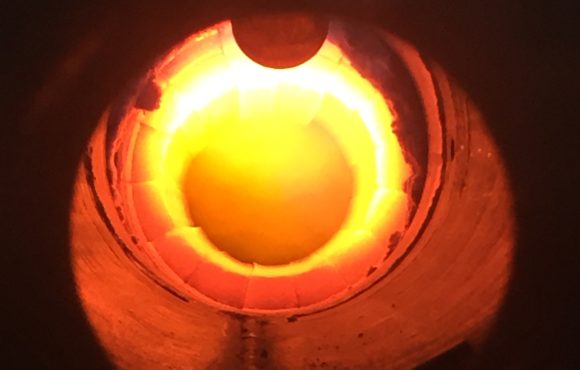

Our team has extensive experience designing, building, and controlling NFPA 86 Class C “Standard for Industrial Furnaces Using a Special Processing Atmosphere” (formerly NFPA 86C) burners and combustion management systems.

Principal Technology is a full service engineering firm with additional support for system integration, fabrication, sulfur recovery, amine treating, and a wide selection of turnkey solutions.

Call 214-239-3900 or send us a message.