Process Equipment Modules

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

learn moreSystem Fabrication Services

Principal Technology's welding department has extensive Stainless Steel piping and structural steel fabrication experience. Our welders are qualified to ASME XI and AWS D1.1 and 1.6.

get in touch

Stainless steel fabrication is often used for its corrosion and temperature resistance. Under the right circumstances, stainless steel can be the more cost-efficient solution when considering the post-fabrication surface prep and coating requirements for traditional carbon steel pipe and structural systems.

Our fabrication shop and welders are experienced with stainless steel handling, fabrication, and welding. Our shop personnel understand the importance of protecting stainless steel from cross-contamination with ferrous metals during all phases of the fabrication process.

With qualifications in ASME Section IX and AWS D1.1 and D1.6 using SS TIG and FCAW process, 6G positions, for piping to 24″ NPS, and metal thickness up to 3/4″, our welders are ready to tackle the most challenging SS and alloy fabrication projects.

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

learn morePackaged Combustion Fuel Piping Systems provide tight integration of safety control, instrumentation, and critical burner fuel piping into a unitized system that is Factory Tested before shipping to your plant.

learn moreOur team can build the system to meet your filtration challenges for water, wastewater, sour water, amine, gas conditioning - Carbon filtration, cartridge, bag and sand media filters, ozonation, biological treating, and more.

learn moreNot all piping is equal... Specialty piping spools, including flow meter runs, welded jacketed piping systems, and alloy piping spools, can take a little extra care and attention. Principal Technology's fabrication group is experienced in meeting these challenges.

learn morePrincipal Technology has been designing, fabricating, and installing modular process units and equipment skid packages for over 25 years. Our senior managers and leadership team have dedicated most of their careers to the modular system design philosophy.

learn moreModular E-Houses for Power Distribution, Analyzers, and Control Systems constructed from self-supporting Structural Insulated Panels (SIP) or with integral structural steel frames, available with packaged HVAC, pressurization, and purge ventilation systems.

learn more

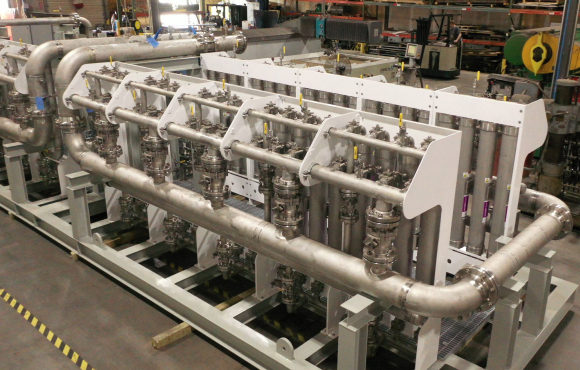

Our fabrication team was contracted to build this CO2 filtering membrane skid package containing extensive stainless steel piping, valves, and fittings. The completed skid assembly was fabricated in our Plano, Texas facility, with all equipment, piping, valves, instruments, and analyzers pre-installed and tested before shipping to our customer’s East Coast facility.

Our shop fabricated multiple 10″ and 12″ pipeline valve risers for a client in West Texas. This project included the SS pipe fabrication, preassembly, and pressure testing of the bolted assemblies before shipping them West.

One of many SS Pump and Meter Skids fabricated by our shop… buttoned up and heading to its new home in West Texas.

Principal Technology is a full service engineering firm with additional support for system integration, fabrication, sulfur recovery, amine treating, and a wide selection of turnkey solutions.

Call 214-239-3900 or send us a message.