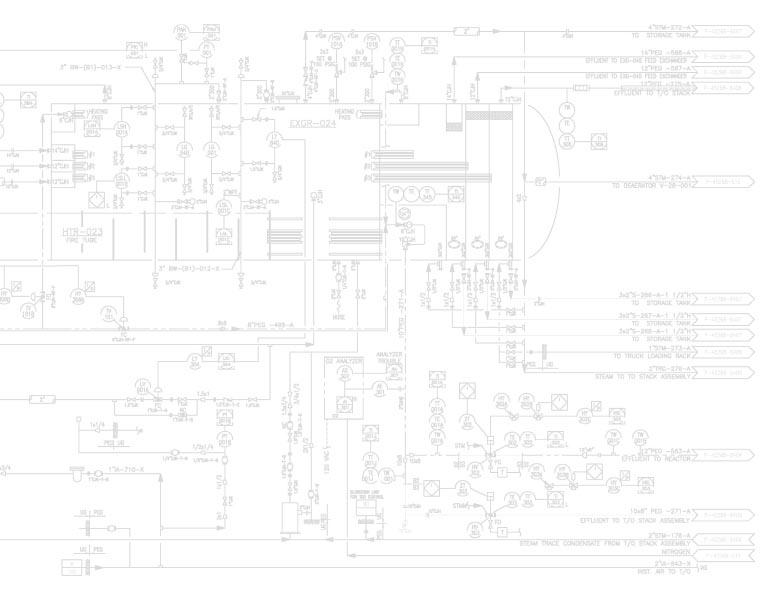

Process Equipment Modules

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

learn moreSystem Fabrication Services

Our team can build the system to meet your filtration challenges for water, wastewater, sour water, amine, gas conditioning - Carbon filtration, cartridge, bag and sand media filters, ozonation, biological treating, and more.

get in touch

The PTI team is well experienced in a broad range of filtration and treating systems from water treatment for large commercial and industrial boilers, ozonation and biological treating, industrial carbon filtration, produced water filtration, amine filter systems, and sour water treating packaged units.

Our team of engineers, designers, and fabricators can tackle your project, whether it be a simple build-to-print pump and filtration skid or a complete turn-key industrial filtration and treating unit… we are here to tackle your filtration and treating challenges.

Modular Process Equipment can reduce plant outage windows, improve construction schedules, increase safety and reduce construction costs by reducing on-site congestion during critical plant production outages.

learn morePackaged Combustion Fuel Piping Systems provide tight integration of safety control, instrumentation, and critical burner fuel piping into a unitized system that is Factory Tested before shipping to your plant.

learn morePrincipal Technology's welding department has extensive Stainless Steel piping and structural steel fabrication experience. Our welders are qualified to ASME XI and AWS D1.1 and 1.6.

learn moreNot all piping is equal... Specialty piping spools, including flow meter runs, welded jacketed piping systems, and alloy piping spools, can take a little extra care and attention. Principal Technology's fabrication group is experienced in meeting these challenges.

learn morePrincipal Technology has been designing, fabricating, and installing modular process units and equipment skid packages for over 25 years. Our senior managers and leadership team have dedicated most of their careers to the modular system design philosophy.

learn moreModular E-Houses for Power Distribution, Analyzers, and Control Systems constructed from self-supporting Structural Insulated Panels (SIP) or with integral structural steel frames, available with packaged HVAC, pressurization, and purge ventilation systems.

learn more

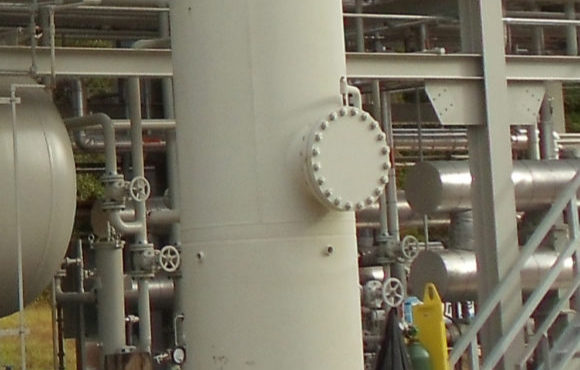

This is one of many carbon filtration systems in our portfolio. We incorporated the filtration subsystem into a larger Amine Regeneration Unit designed and built by our engineering team for a gulf coast plant.

Pre- and Post- particulate filters combined with a properly sized carbon bed designed and built by PTI to meet the filtration demands for this project.

Our client approached us with the challenge to reduce their municipal water costs at their machine wash facility by reclaiming spent wash water, treating, and reusing it in another part of their process. The current technology for direct recycling and filtration systems suffers from maintenance headaches and excessive odor problems and is not an option.

PTI engineers met with stakeholders to understand the unique details of their process, analyzed the reclaimed water samples, and developed a separation and treatment strategy to recycle this waste stream efficiently. PTI’s engineers designed the process with the goal of using common industrial equipment to keep the system cost-efficient and minimize supply chain challenges for custom components.

After completing the design and reviewing the 3D Model with our client, we fabricated the initial prototype in our Plano, Texas facility. With the system in our shop, our engineers and shop personnel completed an initial function test and performance run before shipping the unit to our client’s facility.

Once onsite, our engineers provided operator training and assisted with the initial start-up and full-capacity operation. The unit is in operation and undergoing long-term performance testing. Our client has targeted the system to become the standard water reclamation module for all their US-based facilities.

Principal Technology designed and built this water pump and filtration skid in our Plano, Texas facility. The engineered system required structural, process & mechanical, electrical, and control design. The completed skid with all electrical, control, and associated piping and valves was packaged for export and shipped to our client’s plant.

Principal Technology is a full service engineering firm with additional support for system integration, fabrication, sulfur recovery, amine treating, and a wide selection of turnkey solutions.

Call 214-239-3900 or send us a message.